The role of ITSM in modern manufacturing

Over the past few years, the manufacturing industry has seen rapid digitization to improve production techniques with smart manufacturing technology. Propelled by Industry 4.0 and Industry 5.0, manufacturers are moving away from archaic and disparate manufacturing systems to digitally transformed manufacturing with connected smart manufacturing systems that take advantage of advanced technology, like IoT, AI, ML, and big data.

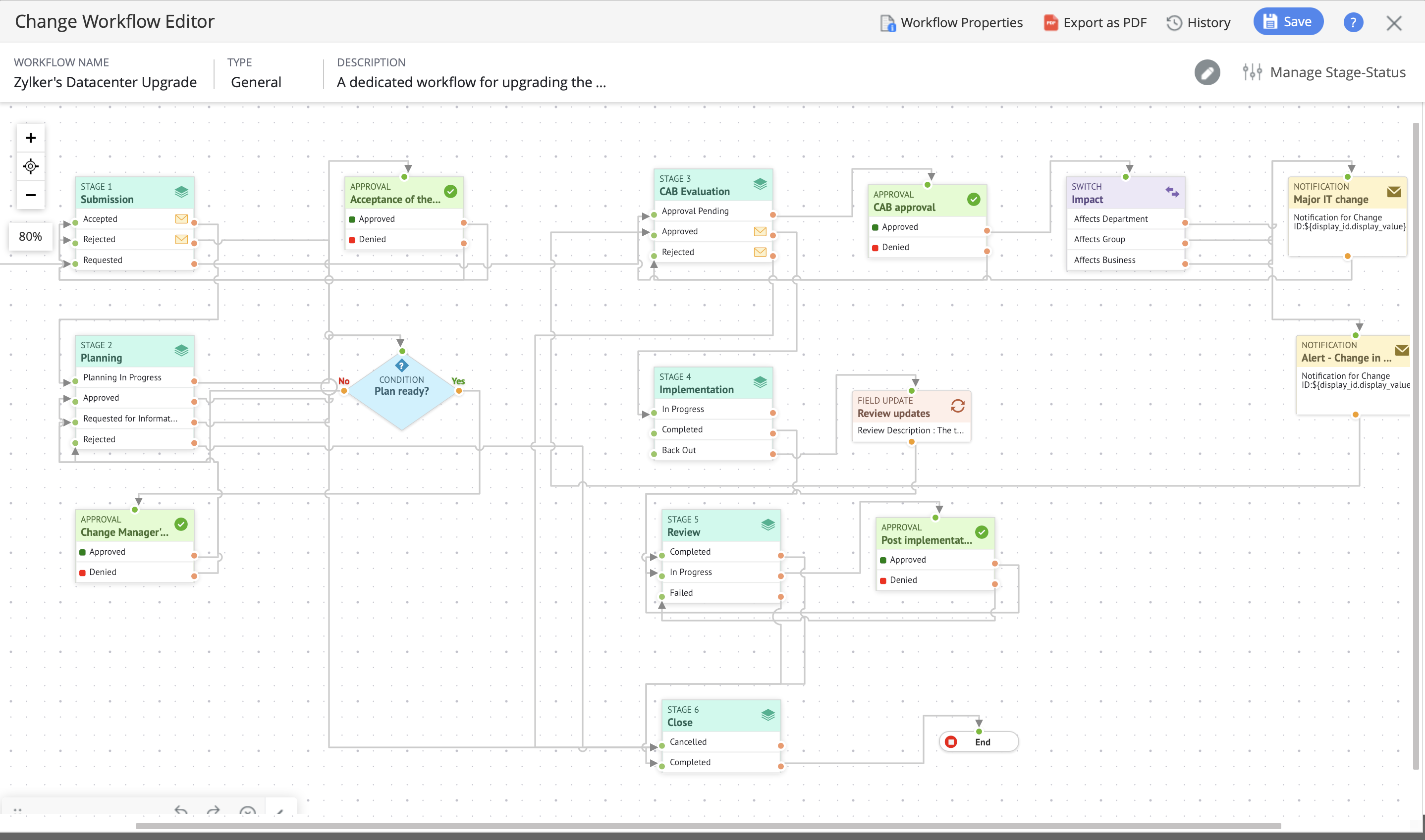

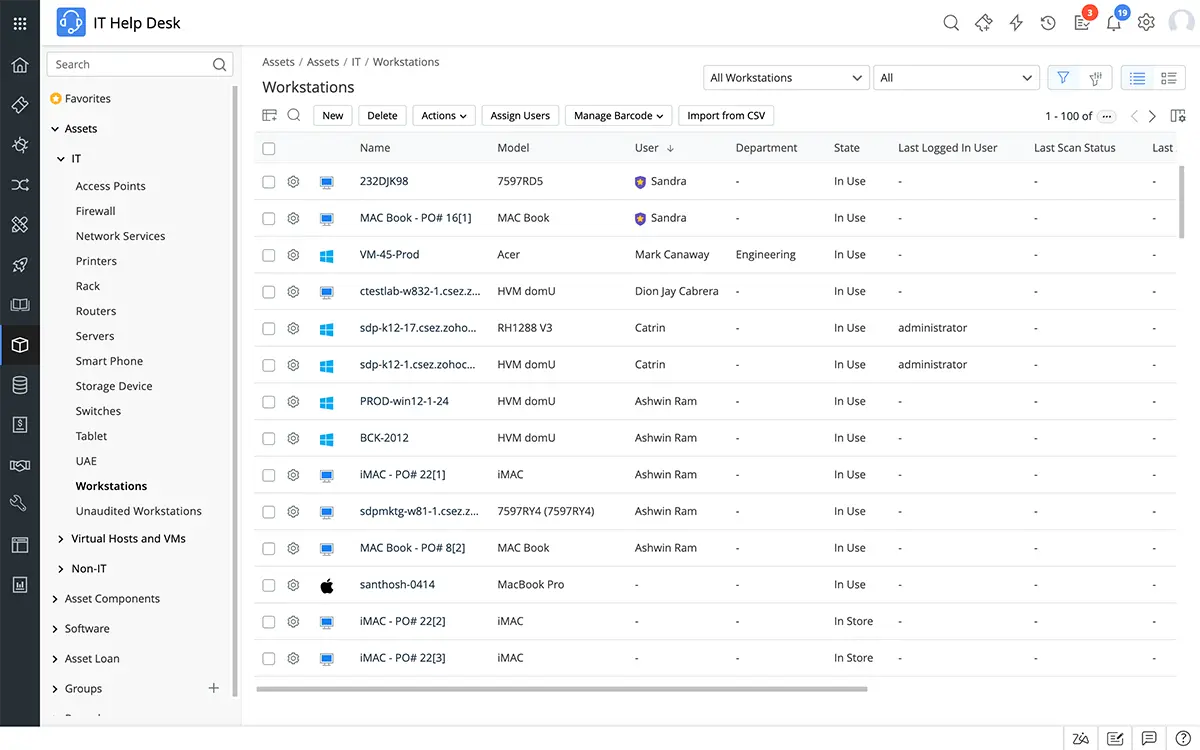

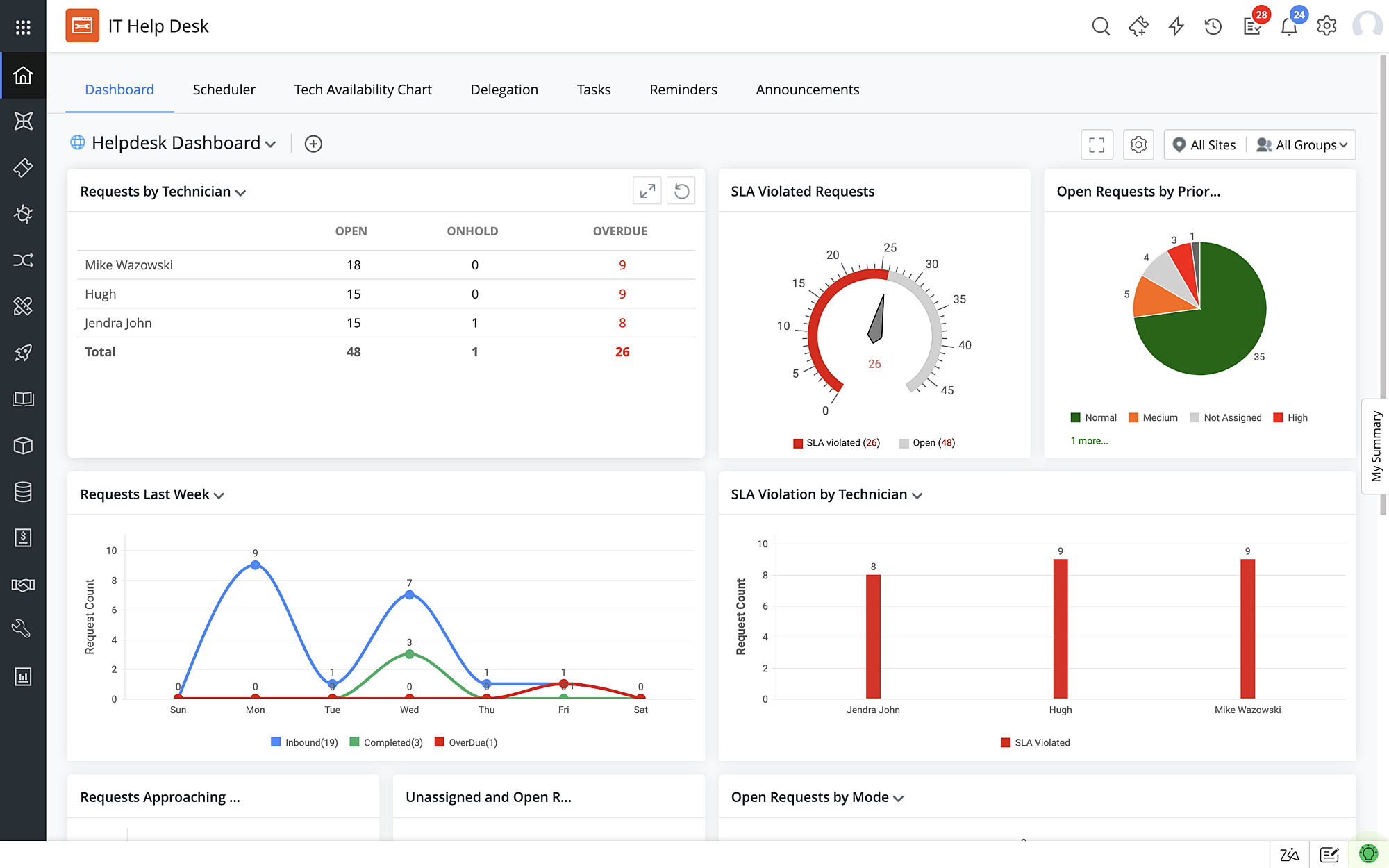

This constant trend of digitization has driven manufacturers to adopt smart equipment and software that are connected to the larger IT environment to measure equipment health automatically and proactively flag anomalies. IT infrastructure now plays a bigger role in manufacturing, and it's vital that the IT team stay on top of IT incidents to eliminate manufacturing downtime.

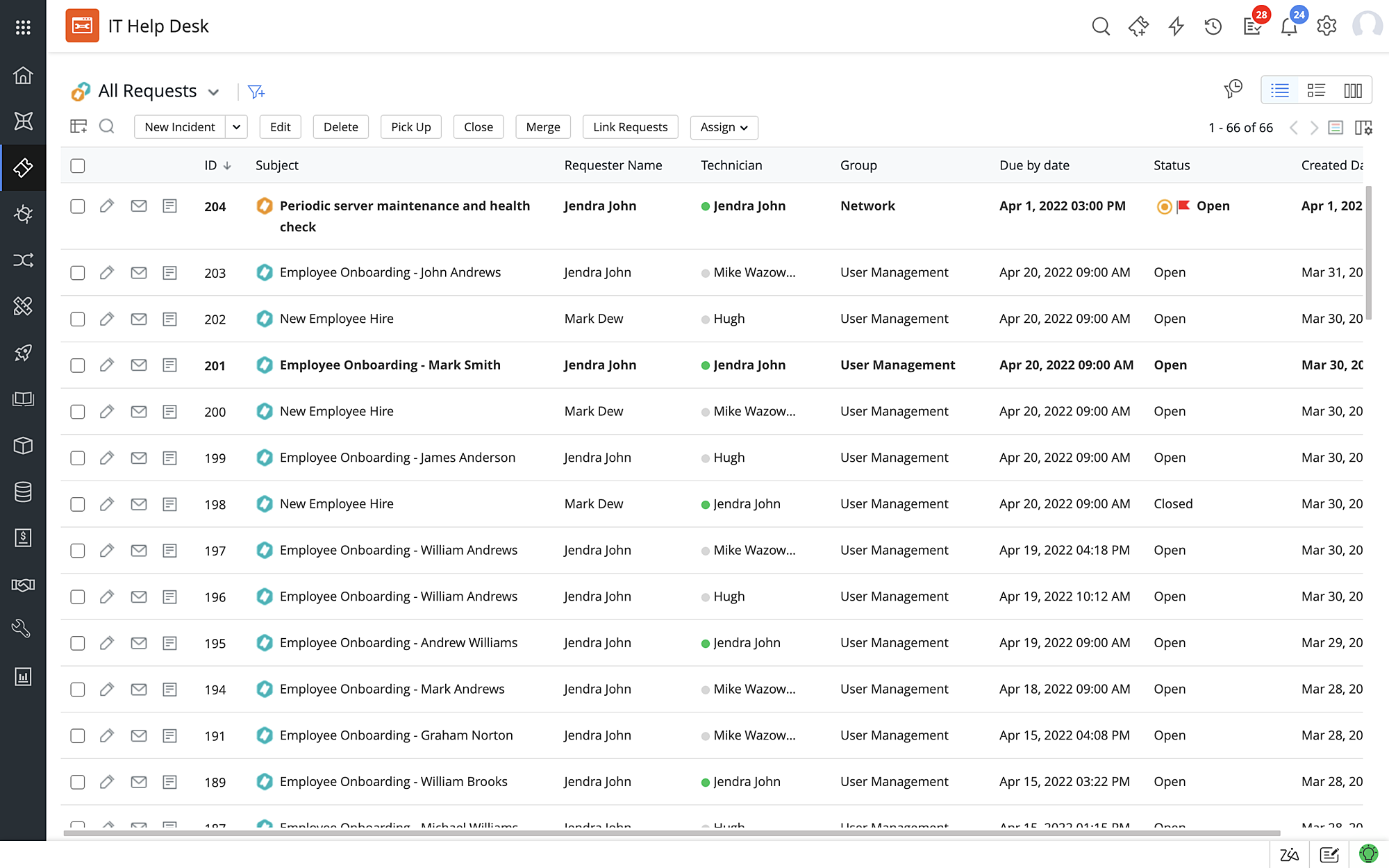

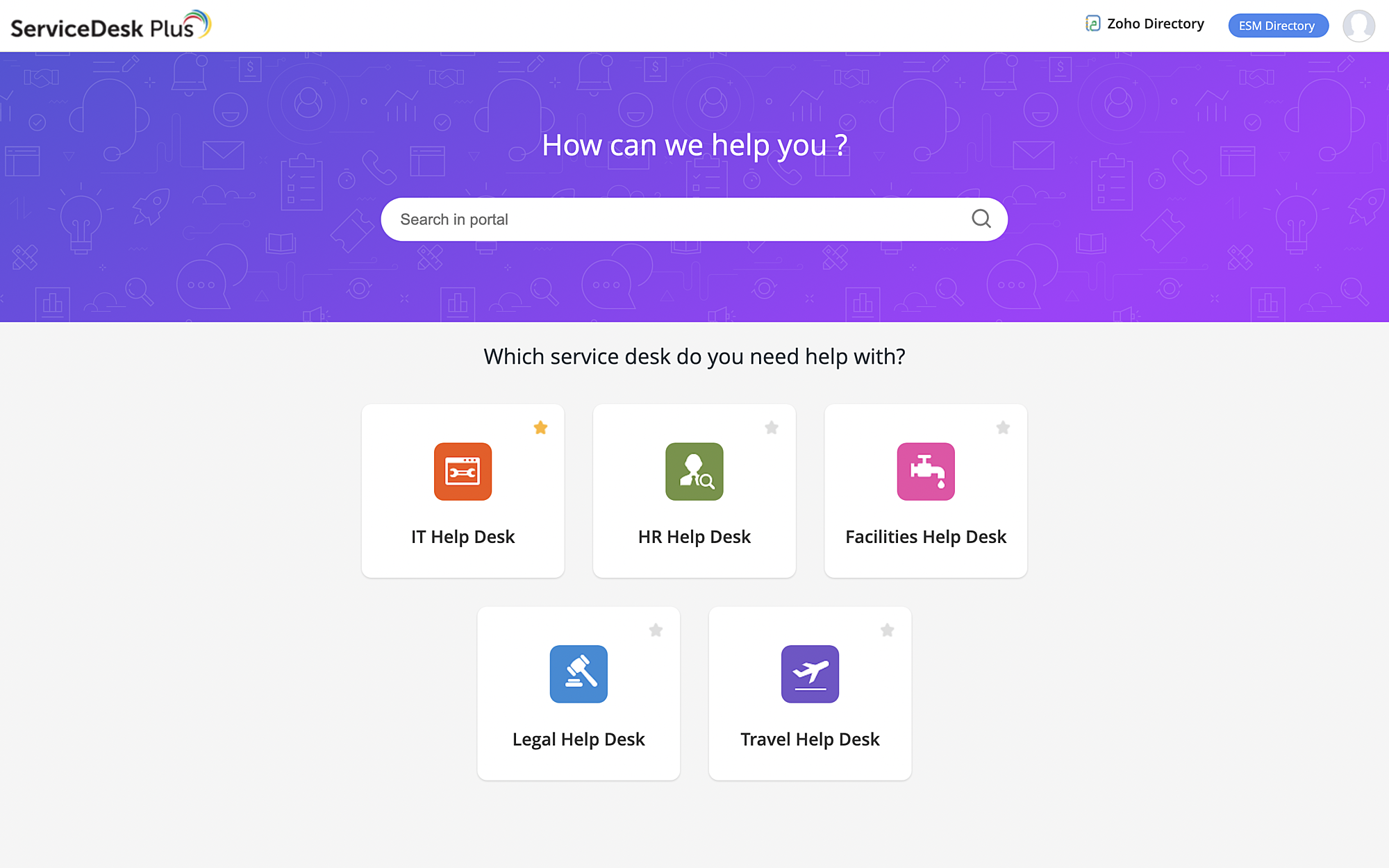

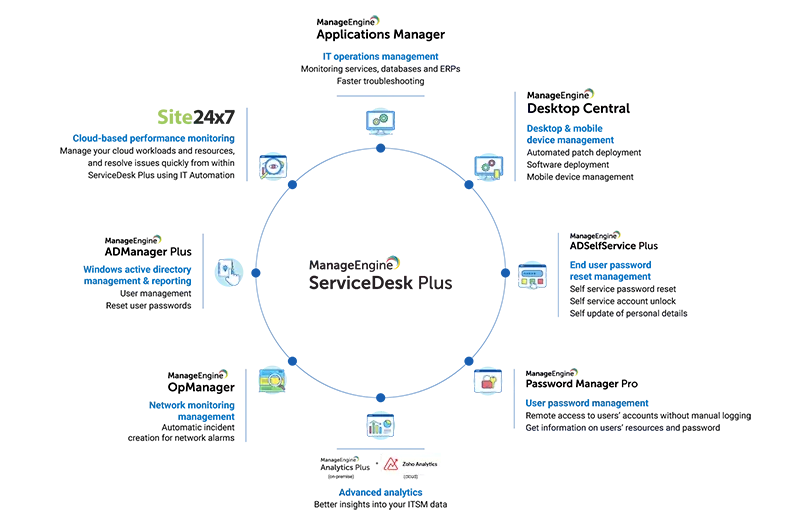

An ITSM solution ties things together and gives manufacturers a strong foundation to establish effective ITSM practices to manage IT infrastructure in an organized, structured way. Additionally, it helps manufacturers streamline service delivery for users and provide a good user experience, something that was often neglected. Delivering services to employees and other end users on time improves employee productivity and keeps customers loyal, which in turn helps manufacturers achieve better margins in increasingly competitive spaces.

5 ITSM challenges that manufacturing companies may face: